Latest modern construction materials

Here would be several benefits for preferring wood over glass in architecture. Wood has lower thermal conductivity which would help to keep a building at more consistent temperature and make it easier to reach higher energy efficiency.

Wood also has good mechanical properties, such as strength, toughness and low density, which makes it even more attractive replacement for glass. The potential of transparent wood is not only in construction; it can also transform electronics.

2. The cooling system in bricks

In a recent study student at the Institute of Advanced Architecture of Catalonia invented a new material technology that has a cooling effect on building interiors. They used a combination of clay and hydrogel to create a cooling effect that comes from the presence of the hydrogel in the structure. This will absorb water that is released to reduce the temperature during hot days. Along with the ability to reduce indoor temperature by 6 degrees Celsius. This also involves the addition of water vapor to the air, resulting in a lowering of air temperature. It a way this process mimics the water-filled ceramic vessels effect. The porous and lattice-like ceramic brick is 3D printed that interlocks the bricks to create a strong bond when set in a mortar and then will absorb the water in their micro-pores kind of like a sponge effect. As the air passes through the bricks lattice structure the water is held in the pores and evaporates, thus bringing cold air into the interior environment and lowering the temperature. This method of material technology can be very innovative for areas with extremely high temperatures. This material in the architectural industry also becomes a living thing as part of nature and not outside. The components work as organisms with biological systems that are live operations between the structure and its surroundings. This material technology illustrates multiple innovative qualities that are social and behavioral in the environment that surpasses the original use of bricks and putting it into a more creative and efficient use.

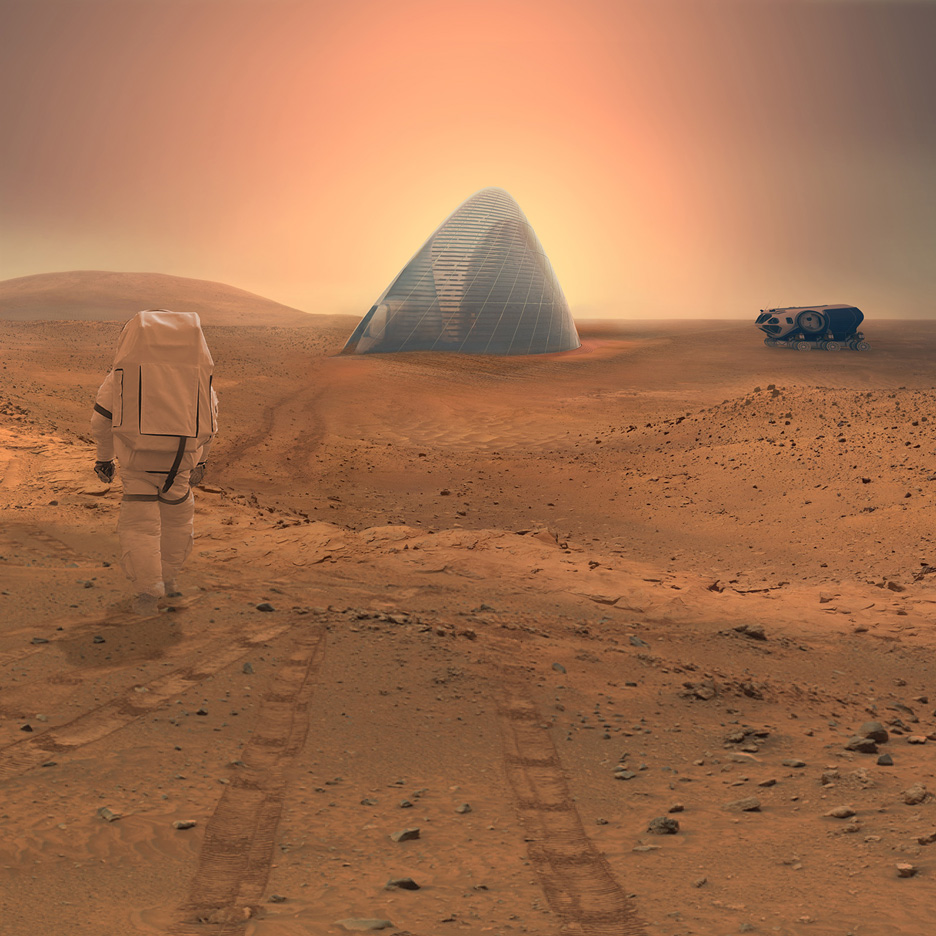

A team of Illinois-based scientists have developed a form of "Martian concrete" that could be used to build architectural structures on the surface of the red planet.

Lin Wan, Roman Wendner and Gianluca Cusatis from Northwestern University have formulated a construction material that combines Martian soil with molten sulphur, which they claim could be used to build an entire village on Mars.

The most important feature of the material is that – unlike regular concrete – it is produced without water, which is in scarce supply on Mars. The majority of water that exists on the planet today is frozen.

Another advantage of the material is that it it entirely recyclable, so it could be melted down and reset into a new form. It also has a natural resistance to acid and salt, and can endure very low temperatures.

Our homes, furniture, and possessions could one day become part of the natural order. New York-based non-profit organisation Terreform ONE in collaboration with Genspace, have designed a series of benches made from organic materials that decompose once placed in a biological environment.

The prototypes form part of a series of experiments with biologically produced furniture that is grown rather than manufactured in the traditional sense.

“This low-tech, low energy process is pollution free, and contains a low embodied energy as part of a local ecosystem,” writes Terreform ONE. “The technology is easily transferable to the developing world. At the end of the useful product life cycle, Mycoform can be composted and safely reintroduced back into the environment, where it can be naturally biodegraded.”

8.Floating piers

A Bulgarian-born living in New York since 1968, Christo (Christo Vladimirov Javacheff, b. 1935) is world-known for his large-scale artworks which turn architectures and landscapes into gigantic pieces of art and create a dialogue between the artist’s mind, the visitors, and the urban and natural environments they encompass.

9.pollution absorbing bricks To combat the pollution from brick kilns, MIT students developed the 'Eco BLAC brick. ' This specially designed brick is made from 70 percent leftover boiler ash waste, which would otherwise clog up local landfills. The rest of the brick is composed of sodium hydroxide, lime and a little bit of clay.

To combat the pollution from brick kilns, MIT students developed the 'Eco BLAC brick. ' This specially designed brick is made from 70 percent leftover boiler ash waste, which would otherwise clog up local landfills. The rest of the brick is composed of sodium hydroxide, lime and a little bit of clay.

10.Self-healing concrete

The process of self-healing of cracks or self-filling up of cracks by the help of bacterial reaction in the concrete after hardening is known as Self-Healing Concrete.These types of bacteria can be in dormant cell and be viable for over 200 years under dry conditions.

0 Comments